(一) Compared with the shell-and-tube heat exchanger

Panstar fully welded heat exchanger extends the range of applications of gasket heat exchanger, and having high temperature, high pressure, corrosion resistance and high heat transfer efficiency advantages, it can replace the traditional shell-and-tube heat exchanger.

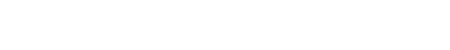

1.Compact structure, low cost of initial investment, covers small area .the same heat transfer area required covering an area the size of shell-and-tube 1/3.

Space-saving indirect savings in investment costs

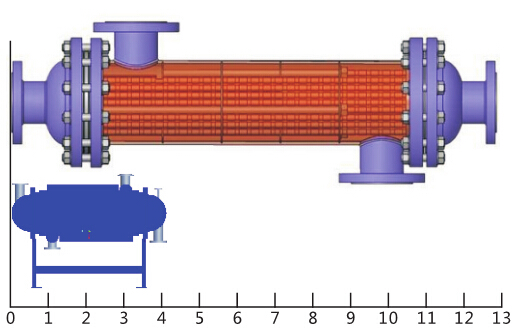

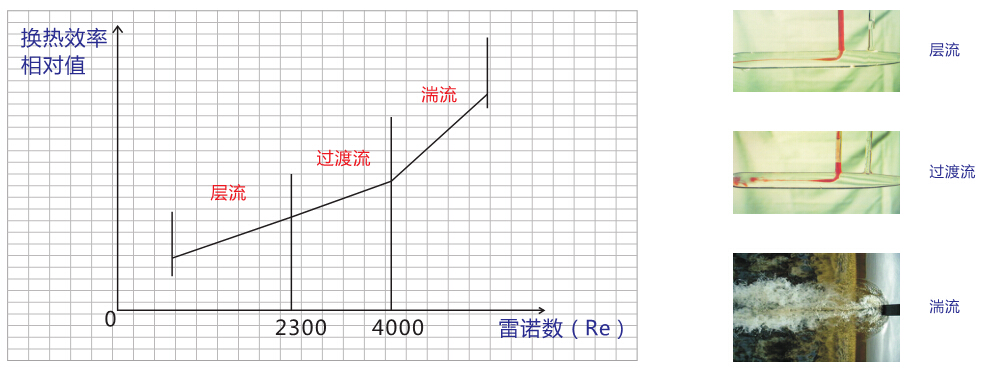

2.High heat exchange efficiency, realizing small temperature difference heat transfer in turbulent flow, heat transfer area is small, low degree of dirt, liquid holdup small.

3.Cleaning is easier, shell-and-tube cleaning is difficult cleaming, and sometimes need to remove Tube bundle, but fully welded heat exchanger can disassembly cover plate for cleaning the inner core region.

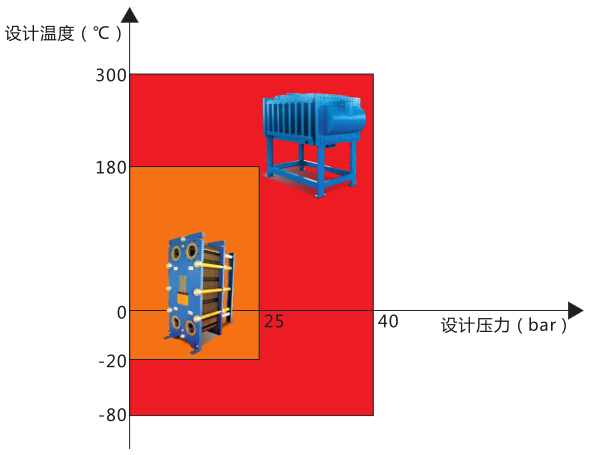

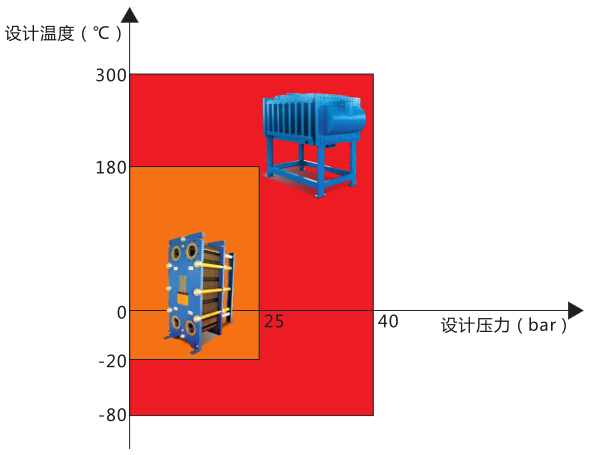

(二) Compared with the removable plate heat exchanger

1.high temperature, the temperature can be up to 300 ℃;达300℃;

2.high pressure, pressure up to 4.0Mpa;

3.resistance to corrosion and can be used for corrosion mediums on the sealing gaskets of the occasion;

4.it can be used for inflammable, explosive and toxic media production technology with high safety and environmental requirements;

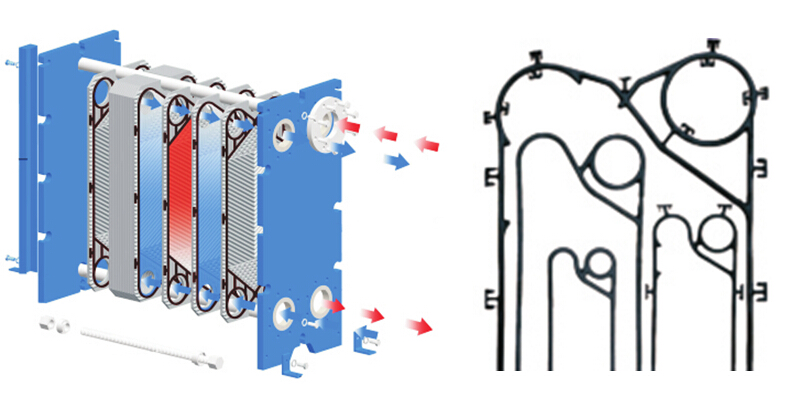

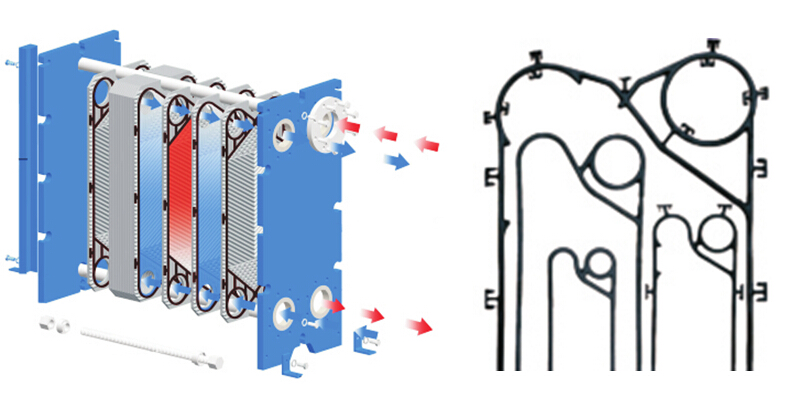

Detachable plate heat exchanger is resistant to temperature and dielectric depends entirely on the gasket, which also limits the range of gasketed plate heat exchanger used. Fully welded heat exchanger is welded directly by plate , there is no gasket, wide range of applications.

5.no angle holes, increasing the effective heat transfer area.

In the case of other conditions are the same: the same size plate, due to fully welded plate no angle holes, so effective heat transfer area more than gasketed plate heat exchanger .

(三) Compared with other fully welded heat exchanger

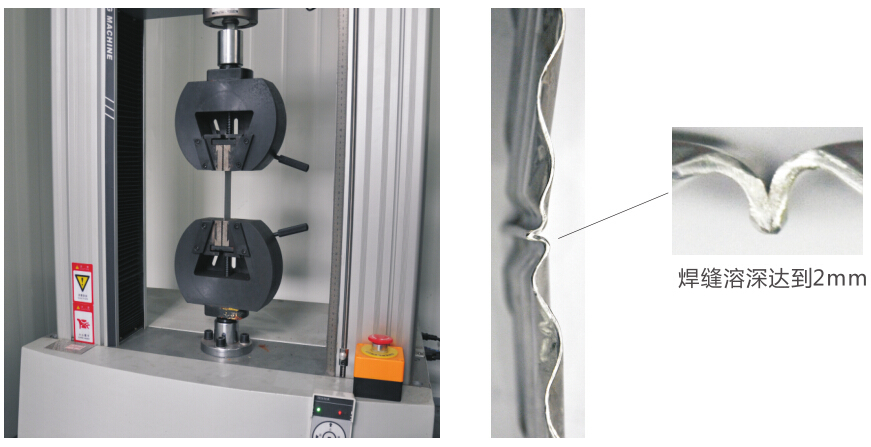

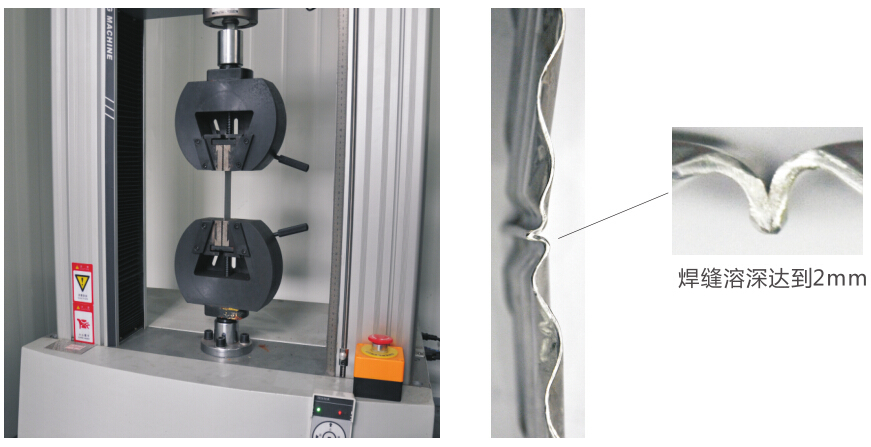

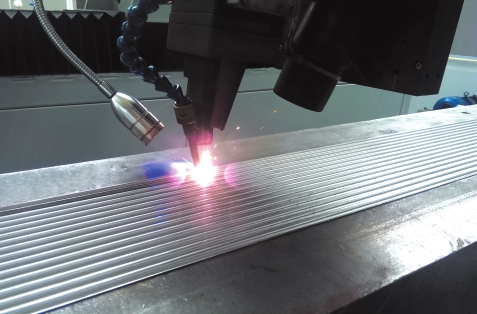

1.welded high strength Plate welding strength than the parent material;

2.small heat-affected zone, thermal deformation. reduces corrosion, avoid stress corrosion cracking;

Laser welding Traditional argon-arc welding

Laser welding Traditional argon-arc welding

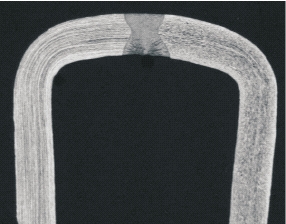

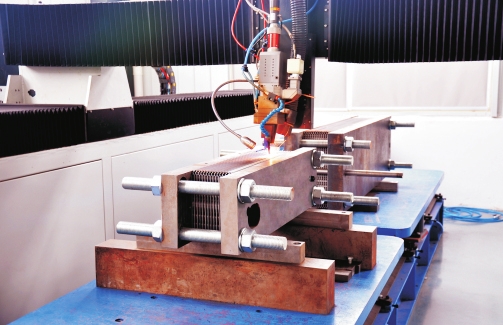

3.Automatic laser welding, welding stability, plate thickness can be welded to the 0.6mm, improves the efficiency of heat exchanger, reducing upfront equipment costs;

Panstar Automatic laser welding Other manufacturers manual argon-arc welding

Panstar Automatic laser welding Other manufacturers manual argon-arc welding

4.Contactless soldering, no mechanical deformation, weld appearance;

Panstar Laser welding bead Other manufacturers TIG weld

5.Welding machine after shrinkage less distortion, overall dimension can guarantee;

5.Welding machine after shrinkage less distortion, overall dimension can guarantee;

Panstar welding no shrinkage others can be shrinkage

6.channel nozzle size consistent with the over size,Tube box taking over should be no protruding .ensuring media will not be stranded in the heat exchanger;

6.channel nozzle size consistent with the over size,Tube box taking over should be no protruding .ensuring media will not be stranded in the heat exchanger;

Panstar Interface processing others Interface processing

7.Pretension supply device, Avoid running liquid jitter impact wear;

7.Pretension supply device, Avoid running liquid jitter impact wear;

8.Plate mold using delayed clamping design, tensile deformation of sheet small, small plate thickness reduction.

Contace us

0512-67543315

yzpst@pstphe.com