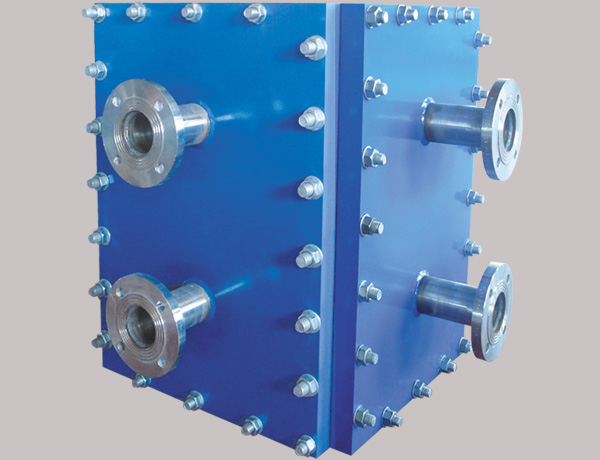

Plate and frame fully welded heat exchanger

Advantages: Panstar plate &frame fully welded heat exchanger combined with plate heat exchangers and shell-and-tube heat exchanger advantages, it has high efficiency compact, high temperature resistance, good sealing performance, security and reliability, and it can be used under high pressure and temperature conditions.For steam condensation and liquid-liquid heat transfer conditions, especially for electricity, petrochemicals, coking, pharmaceuticals, metallurgy, refrigeration, heat of the pulp and paper industry and other industry-specific media requirements.

Through the process of setting, ensuring reasonable matching of loss of heat transfer and flow resistance of the device. Shell using hexahedral removable structure. It can meet the process requirement for carrying out mechanical cleaning and chemical cleaning of equipment.

Full features:

1.Compact structure, small covering area , high efficiency, and high pressure (up to a maximum of 4.0Mpa), resistant to high temperatures (temperatures up to ~ 300℃), reliable operation.

2.High heat transfer efficiency: heat exchange medium is realized through the plate,the plates was pressed by special mould , the structure like removable plate heat exchanger. It has high heat transfer efficiency,Large flow , small fluid pressure drop, less heat loss and so on.

3.Easy and flexible: using one mold can press different length and specification of plates, forming the same width products, meeting more needs of working conditions.

4.Applies range wide: the plates and the pressure plate both using welding structure, it can work well for temperature ≤ 300 ℃, pressure ≤ 4.0Mpa or the media has corrosion of occasions and flammable.easy burst,toxic media and the high environment requirements security , and liquid media of cooling, warming, evaporation, Therefore, Both the advantages of plate heat exchanger, with high temperature & pressure .

|

- 上一篇:没有了

- 下一篇:Fully welded heat exchanger

Contact us

0512-67543315

yzpst@pstphe.com